We are Trader (from reputed Manufacturers), Supplier, Exporter of Image Analyser Systems from Pune, Maharashtra, India. As a leading Calibrator, Repairer; we provide Calibration Services, AMC (Annual Maintenance Contract) Services, Repairing Services for this product. We majorly target customers from Aurangabad, Mumbai, Kolhapur, Satara, Sangli, Nashik, Thane, Talegaon, Chakan, Sanaswadi, Ranjangaon, Pimpri, Chinchwad, Shirwal, Goa.

Grain Size Estimation

With automatic grain boundary re-construction Analyzer can take any ordinary / practical image for processing. It cleans the same, automatically joins the broken grain boundaries and makes the image perfectly suitable for further automatic analysis. Does not call for manual intercept marking.

Options exist for intercept method (parallel lines or concentric circles depending on the aspect ratio of grains), planimetry method, comparison method. Also results can be obtained in the form of grain size distribution, individual grain area, its perimeter, L/D ratio, mean lineal intercept length, average grain size, largest grain size in microns etc.

Grain size analysis of ceramic, Copper and other materials can be determined as per

the individual method.

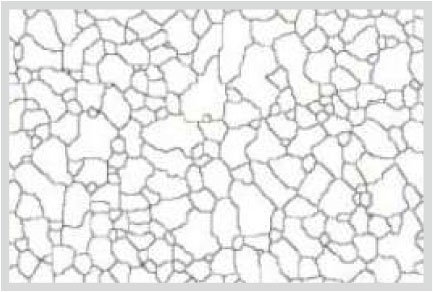

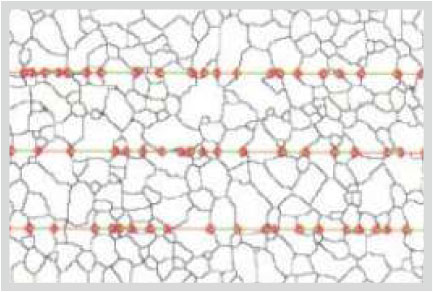

Original Image

Original Image

Process Image

Process Image

Grain Size 6.5

Grain Size 6.5

Phase Analysis

Based on the gray level difference as many phases can be identified and measured to its fine perfection based on thresholding gray levels. With automatic and manual methods histograms can be generated.

Original Image

Original Image

Process Image

Process Image

Nodularity Analysis

Graphite features as per their shape factors are separated in type I to Type VII. Percentage nodularity is Distribution can be obtained as per the size.

Image stitching facility can be used if analysis is required on total 1 mm sq. by stitching/tiling of images.

Under the etched condition one can directly estimate percentage of graphite, pearlite and ferrite.

Original Image

Original Image

Process Image

Process Image

Flake Analysis

Graphite flakes are classified in size class from 1to 8 as per their length. Min, Max flake length and distribution curve can be plotted. Also separation of the flakes as A, B, C, D is possible in normal cases.

Original Image

Original Image

Process Image

Process Image

Particle count and size classification

Individual particles in the given field of view can be marked, separated as per their sizes. Distribution curve can be plotted.

Linear Measurements

Measurements like plating, coating, decarburisation, inter lamellar distance, degree of banding etc. are done manually or automatically depending on the image contrast. Arbitrary line measurement helps measuring distance in any direction.

Inclusion Analysis

Given a good polish, accurate results can be obtained by separating and rating inclusions. One can also intermediately see the classification and can correct or edit the same. Advanced modules can also correct few artifacts like scratches on the samples. Automatic motorized stage measurement option can compile the results of multiple fields and the same can be expressed in desired format.

Original Image

Original Image

Process Image

Process Image

Multilayer Coating Measurement (Tribology)

In the study of measurement of multilayers of CVD coatings software measures layers' thickness automatically. This is supported by ball crater instrument with necessary accessories.

Aluminium Module

Other Module

Retained austenite (by comparison), Carbide distribution (by comparison), Millipore particles analysis, Cement analysis, PCB analysis, Degree of banding.

Data Base Maintenance, Reports

USB Digital Camera

USB Cameras are imaging cameras that use USB 2.0 or USB 3.0 technology to transfer image data. USB Cameras are designed to easily interface with dedicated computer systems by using the same USB technology that is found on most computers. EO USB Cameras are available in both CMOS as well as CCD sensor types making them suitable across a larger range of applications. USB Cameras contain out-of-the-box functionality for quick setup. USB Cameras using low power USB ports.

SDAS Measurement

SDAS Measurement

Porosity Measurement

Porosity Measurement

Cuboids Measurement

Cuboids Measurement